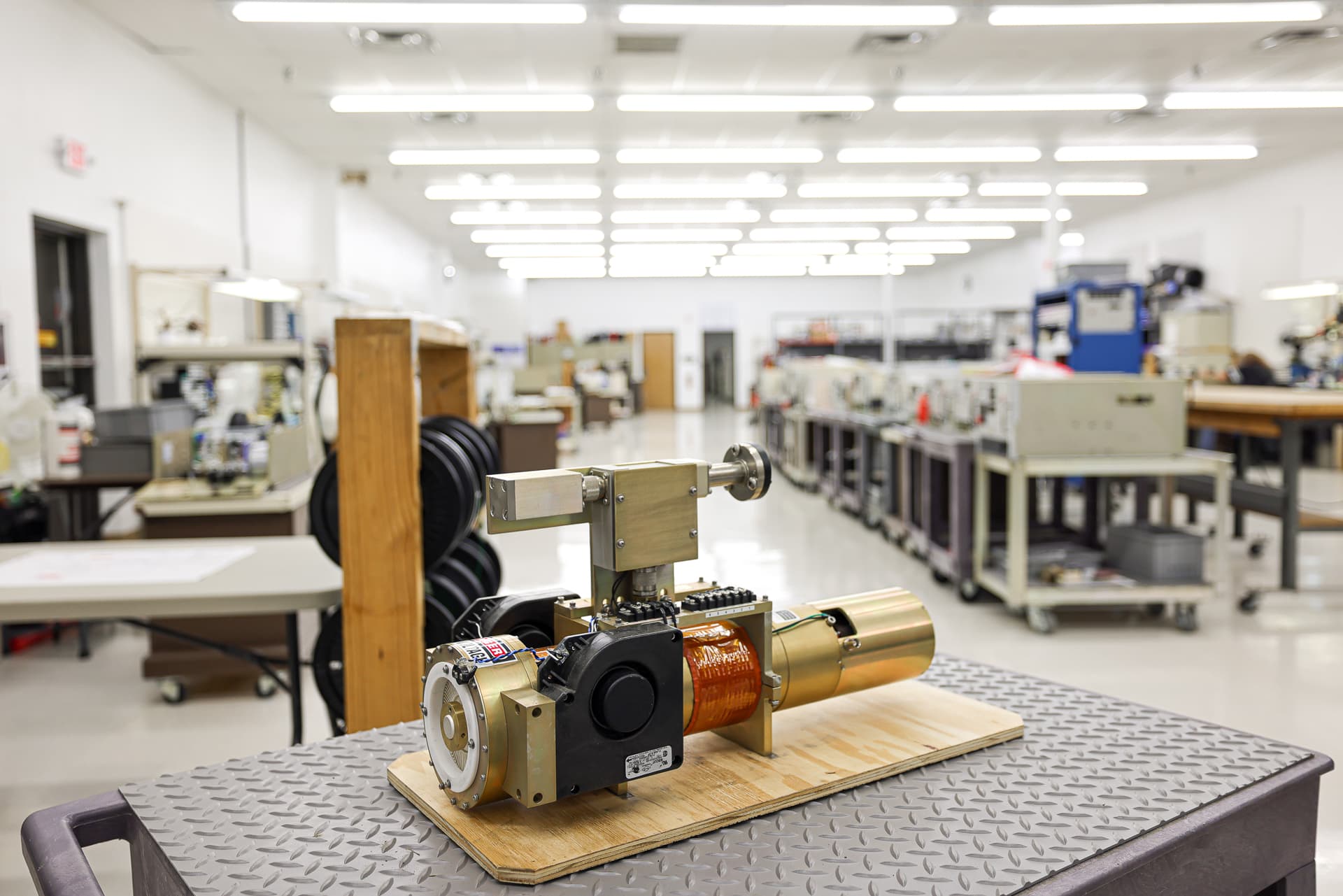

Factory Tour

Our current facility was built in the year 2000, and expanded in 2020. We have a combined total of over 40,000 square feet of floor space for our offices, fabrication and inventory requirements. To ensure the highest quality and reliability, our factory designs and assembles our own circuit boards, wiring harnesses, transformers and power supplies.

Our internal machine shop incorporates state of the art CNC mills for creating parts for precision chassis assembly.

Our stock room contains a very large number of parts to ensure quick assembly of new orders, and if a repair is ever needed, a quick turn-a-round to ensure minimal service interruption.

We create extensive product manuals that include alignment procedures as well as schematics to aid in field maintenance and repair, and technicians are available to answer any questions over the phone or by e-mail.

The test department uses calibrated precision test equipment and thoroughly tests each unit, ensuring specifications are met and performance is documented.

Each unit passes through QA before being packaged and shipped using high quality reusable shipping crates.